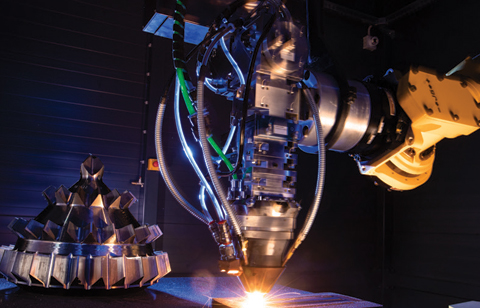

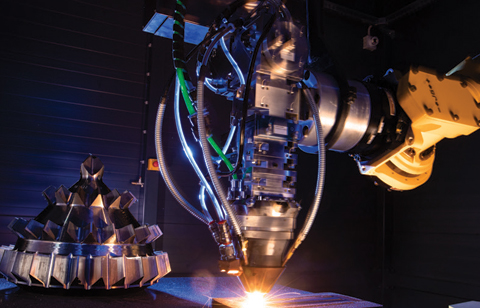

The drilling and minerals mining industry has always been facing a perennial need to enhance productivity at a lower cost. While this need continues to burden the operators in this industry, the current pandemic fears and lockdowns have posed an altogether new supply chain challenge in the form of maintaining continuous delivery. At this concurrence, NiUW Glinik, one of the largest European drilling tools manufacturers operating in the mining and industrial sectors, comes to the forefront with nearly 140 years of experience. With its rich culture and heritage, NiUW Glinik understands and manages the operations during the crisis, at the same time implementing its cutting-edge robotised solution - a project performed together with Polish National Centre for R&D and country’s most experienced Science and Technology universities. The project’s (POIR.01.01.01-00-0705/18-00) aim is to develop new hardfacing material solution and process automation using the Laser Metal Deposition (LMD) technology. And the achieved results of this project are very promising, and further testing will confirm the future of the newest technology, bringing even higher durability of our LMD enforced product. This technology will extend the durability of tools and bring strong support to the energy transformation efforts.

Such innovations bring more automation to the production process and ensure that any of the manpower risks related to the pandemic, will not impact the delivery to the customer.

Grzegorz Sidor, CEO of NiUW Glinik, remarks on the importance of this process by stating, “There are a number of values connected to running a business, and credibility is one of the critical ones. With this ideology, NiUW Glinik prepared and maintained special conditions during the pandemic yet never stopped the operation and delivered continuously.” In addition to dealing with the challenges in supply chain management, NiUW Glinik also resolves the long-standing question of cost-effectivity juxtaposed with quality assurance.

Sidor notes: “Customers often find a trade off in the market, and most of the manufacturers are looking at the ratio between quality and cost. However, we are not giving up on quality while constantly fighting to be more cost effective.”

While these solutions provide merely a glimpse, NiUW Glinik delivers products to different verticals such as mining/ minerals, oil and gas, hydrogeology, geotechnical/construction, and HDD, by identifying each of these areas’ shortcomings and help its clients solve them. In order to cater to the customer needs of every individual sector, the company has a wide range of products in its portfolio: drilling bits, hole openers, and stabilisers with around 1000 of designs within their R&D Engineering. Just in case of drilling bits, NiUW Glinik has options ranging from 2 to 42 inches diameters, which is the largest bit size manufactured in the European market and has hole-openers with up to 56 inches of diameters. The company further enriches its product base by collaborating with the customers, understanding their needs, and implementing continuous feedback from their fields and builds a product that is tailored to their needs. With such customized solutions, NiUW Glinik establishes long term relationships with its clients and drives the business together.

Sidor reinstates the importance of the company’s customers with the narration of a recent success story. He says, a customer of international operations approached NiUW Glinik with the requirement of three large-size drilling bits and hole openers to work in a quite extensive rock formation area and had high pressure on the lead time during the pandemic. NiUW Glinik has delivered the products in almost three times shorter than the expected competitor lead time despite the lockdown and restrictions.